A safe management program is made up of a number of safes that are located in a particular retail location. Each safe contains a small amount of control software. Each terminal unit's processing capacity and memory is limited to well-defined functions. Key control parameters are managed by a central servers. These servers can be a cluster of servers or a single cloud server. The safes themselves do not usually have an internet connection. This means that external hardware is not necessary.

Information collected by safe management system

A safety management system is a comprehensive set of processes and procedures that are designed to minimize the possibility of safety incidents. These systems can be highly effective but cannot eliminate all possible errors because they would not be practical, feasible, workable, or cost-effective. Safety management systems are not able to accurately measure every worker's behavior. This information is nonetheless important in ensuring safety within the workplace.

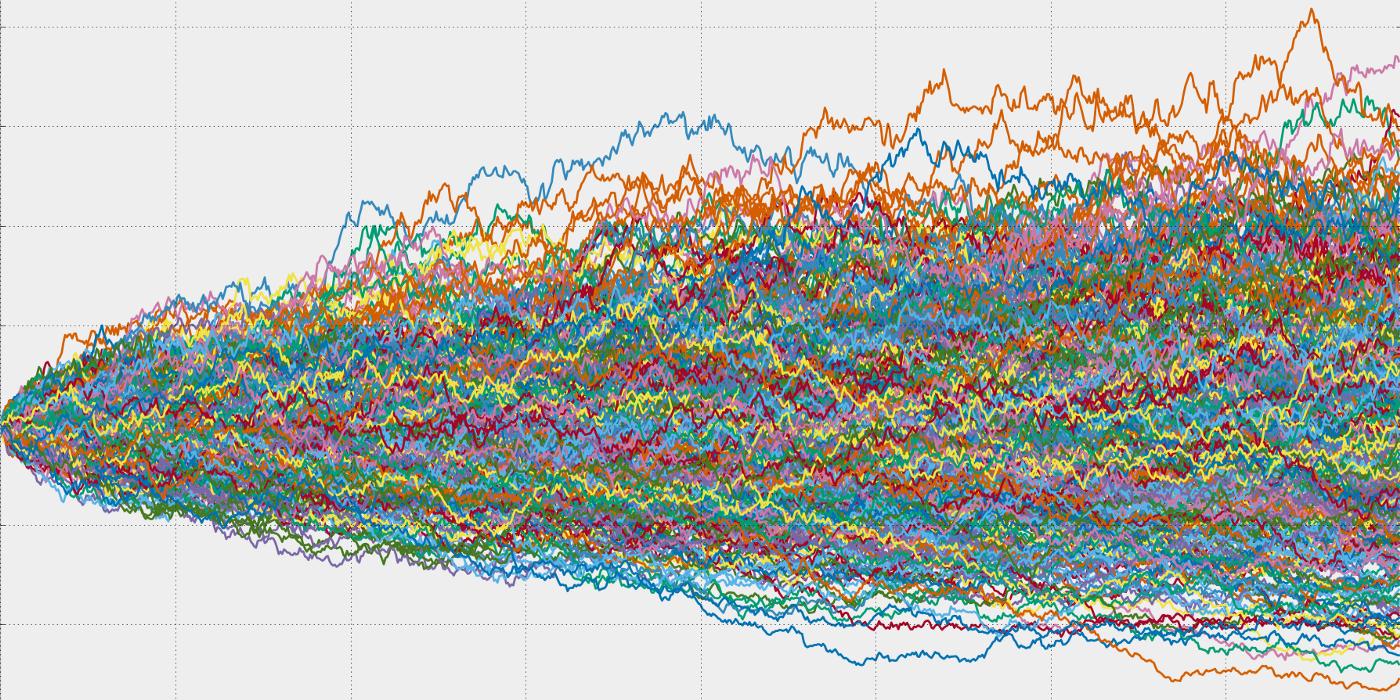

Managers should have access to the system's data and be able analyze it to improve safety performance. Statistical techniques and other data sources are often used for this purpose, and the information should be presented in a meaningful way. Moreover, the reports should be able to identify trends that can help managers allocate resources more effectively. These trends must be accommodated in safety management systems. The information should be easy to interpret and taken into consideration.

Documentation

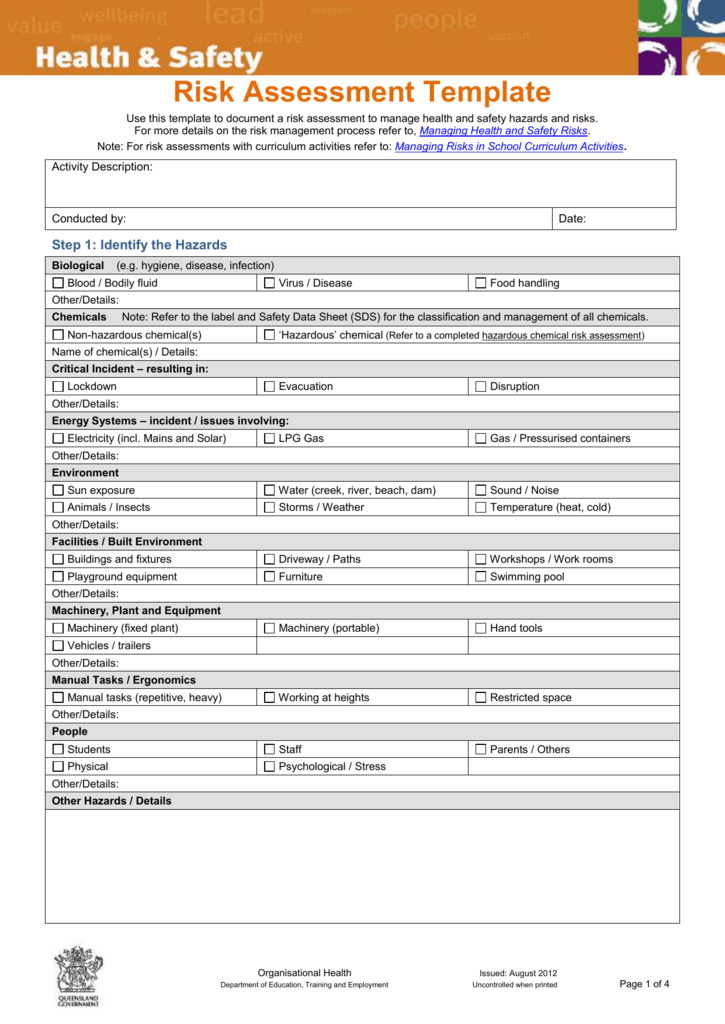

It is essential to have good documentation in order to develop a safe management system. It helps avoid mistakes and allows you to not repeat old mistakes. A management system should normally include processes that handle miscellaneous information, process safety management, labeling and record keeping. Documentation helps to prevent accidents, injuries, or illnesses. Stakeholders have easy access to a complete document that outlines the best practices.

A solid SMS documentation system should include all the applicable national and international regulations, processes and procedures, as well as specific templates for each process and lines of accountability. The documentation should describe the outputs and organization of the safety management system. It should include clear guidelines for maintaining records. For safety documentation to be effective, it must be formally approved by oversight authorities. Further, it should reflect the changes that were made and be up-to-date.

Risk matrix

A risk matrix is a useful tool to help manage risks in an organization. A risk matrix allows you to prioritize risks according to their impact. The risk matrix is based on categories such a Probability and Impact that help to determine the risk level. Once you have determined which risks your business faces, you can use this risk matrix to increase your current risk control and to reinforce your proactive safety culture. Here are some tips to help you create a risk matrix:

First, create the risk matrix. This document shows three types of risk. Each level represents a different type of risk. In Figure A1, the ground level represents the quantitative relationship between severity and probability. The middle floor depicts linear scaling, while top floor carpeting is used. Each column is a risk indicator, and each value is represented numerically. The formula Ri x Cj determines the risk indicator for each cell.

Safety assurance

It is essential to identify the requirements for safety assurance procedures when developing a safety system. Safety assurance procedures should contain all resources, reporting requirements and disciplinary actions. The safety assurance procedure should include all resources, reporting requirements, and disciplinary action. The safety policy should outline the levels of authority that can make safety decisions. The certificate holder should also indicate the types and levels of personnel and resources responsible for maintaining safety management.

Safety assurance was developed as a response to increasing industrial exploitation. The Industrial Revolution brought significant economic opportunities to Western societies. However, the financial imperatives of business owners led the use of a low-skilled workforce that included child labour and rural migrant labor. In such circumstances, it was not uncommon for people to be injured, killed, or have accidents. Safety management was created to counter the exploitation of labour.

FAQ

How do you effectively manage employees?

Managing employees effectively means ensuring that they are happy and productive.

It means setting clear expectations for them and keeping an eye on their performance.

Managers need clear goals to be able to accomplish this.

They must communicate clearly with their staff. They must communicate clearly with staff members.

They must also keep track of the activities of their team. These include:

-

What was achieved?

-

How much work was done?

-

Who did it?

-

How did it get done?

-

Why was this done?

This information can be used for monitoring performance and evaluating results.

What is the difference in Six Sigma and TQM?

The main difference between these two quality management tools is that six sigma focuses on eliminating defects while total quality management (TQM) focuses on improving processes and reducing costs.

Six Sigma stands for continuous improvement. It emphasizes the elimination of defects by using statistical methods such as control charts, p-charts, and Pareto analysis.

This method seeks to decrease variation in product output. This is accomplished by identifying the root cause of problems and fixing them.

Total quality management involves measuring and monitoring all aspects of the organization. Training employees is also part of total quality management.

It is frequently used as an approach to increasing productivity.

What's the difference between leadership & management?

Leadership is about being a leader. Management is about controlling others.

Leaders inspire others, managers direct them.

A leader inspires others to succeed, while a manager helps workers stay on task.

A leader develops people; a manager manages people.

Statistics

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing processes are used to reduce waste and improve efficiency through structured methods. They were developed in Japan by Toyota Motor Corporation (in the 1980s). The goal was to produce quality products at lower cost. Lean manufacturing is about eliminating redundant steps and activities from the manufacturing process. It consists of five basic elements: pull systems, continuous improvement, just-in-time, kaizen (continuous change), and 5S. It is a system that produces only the product the customer requests without additional work. Continuous improvement refers to continuously improving existing processes. Just-in-time refers to when components and materials are delivered directly to the point where they are needed. Kaizen means continuous improvement, which is achieved by implementing small changes continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements are combined to give you the best possible results.

Lean Production System

The lean production system is based on six key concepts:

-

Flow: The goal is to move material and information as close as possible from customers.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban: Use visual signals such stickers, colored tape, or any other visual cues, to keep track your inventory.

-

Theory of constraints - identify bottlenecks in the process and eliminate them using lean tools like kanban boards;

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement - Make incremental improvements rather than overhauling the entire process.