Supply chain success is based on five elements. These elements include collaboration, cost reduction, managing upstream and downstream business issues, and working with suppliers. Identifying and implementing each of these elements is vital for supply chain success. Additionally, supply chain success is affected by government and regulatory agencies.

Five strategies to make supply chain success a reality

If you are looking to meet customer expectations, supply chain management is crucial to any company's success. You must build your supply chain strategy around customer needs to be successful. This means that your fulfillment experience must be consistent with what the brand promises. So, for example, if a company promises speedy delivery, they must be able and willing to deliver. Customers also pay attention to the little things. They value thoughtfulness, which is a sign of the brand's thought process.

Supplier issues are a key part of a successful supply chain strategy. If a supplier is required to pay tariffs, it can lead to delays. This can be overcome by sourcing alternative suppliers and bulk buying before tariffs are in place. Additionally, supply chain software solutions can be used to overcome these delays. Such software can provide precise information about inventory movements and inventory levels.

Success in supply chains is determined by the actions of government agencies and regulators

Several factors influence supply chain success, including government policies and regulations. The United States spends federal dollars to promote domestic capacity and develop markets abroad. It also encourages collaboration between domestic and foreign companies. These mechanisms are public, private, and cross-government. These efforts are designed to help companies meet their dual objectives, which depend on a global supply chain that is trusted and robust.

This is especially true in healthcare, where staff and patients can impact the flow of supplies. Some hospitals might need to have the right size gloves in stock, while others may require specialized medical products. Additionally, financial managers may want to minimize out-of-date products and cut healthcare costs, while others may favor specific brands or types of medical products. In order to disrupt supply chain flow, there can be a lack in coordination and alignment between incentives.

Collaboration with suppliers

Supply chain collaboration is when a company works with suppliers in order to improve its procurement efficiency. It offers many benefits to both the supplier and the customer. Collaboration is more flexible and creates value for both companies than the traditional customer/supplier partnership. Additionally, collaboration allows companies view suppliers as strategic partners who can help them gain competitive advantage.

Supplier collaboration is critical to the success of a supply chain. Each party must find ways to improve the relationship between them in order to maximize collaboration's value. It is possible to improve your relationship with your suppliers by meeting regularly. This will give you the opportunity to listen to their concerns and offer constructive feedback.

Manage upstream and downstream business issues

Supply chain management involves integrating many processes and tasks. The goal is to deliver value to customers as well as other stakeholders. It involves a variety of issues, including financial, reputational, legal, and operational risks. These issues can have a direct effect on the success and sustainability of a supply chain.

It is essential that supply chain managers understand the main issues affecting their business and can develop solid management plans. To address any potential problems, they need to create strong contracts and partner with suppliers and customers. Supply chain managers must also be vigilant and proactive in responding to global economic instability and increasing complexity. For example, political situations may introduce tariffs across trade routes, resulting in increased costs and customs processing times, as well as slowing international shipping.

FAQ

What does the term "project management” mean?

This refers to managing all activities that are involved in a project's execution.

Our services include the definition of the scope, identifying requirements, preparing a budget, organizing project teams, scheduling work, monitoring progress and evaluating the results before closing the project.

What are the steps to take in order to make a management decision?

The decision-making process of managers is complicated and multifaceted. It includes many factors such as analysis, strategy planning, implementation and measurement. Evaluation, feedback and feedback are just some of the other factors.

The key thing to remember when managing people is that they are human beings just as you are and therefore make mistakes. You can always improve your performance, provided you are willing to make the effort.

This video will explain how decision-making works in Management. We will discuss the various types of decisions, and why they are so important. Every manager should be able to make them. You'll learn about the following topics:

It can sometimes seem difficult to make business decisions.

Businesses are complex systems, and they have many moving parts. People who manage them have to balance multiple priorities while dealing with complexity and uncertainty.

Understanding the impact of these factors on the system is crucial to making sound decisions.

You need to be clear about the roles and responsibilities of each system. Then, you need to think about how these pieces interact with one another.

You need to ask yourself if your previous actions have led you to make unfounded assumptions. You might consider revisiting them if they are not.

Asking for assistance from someone else is a good idea if you are still having trouble. They might see things differently than you and may have some insights that could help find a solution.

What are the key management skills?

Managerial skills are crucial for every business owner, regardless of whether they run a small store in their locality or a large corporation. These skills include the ability manage people, finances and resources as well as other factors.

You will need management skills to set goals and objectives, plan strategies, motivate employees, resolve problems, create policies and procedures, and manage change.

As you can see there is no end to the number of managerial tasks.

Which kind of people use Six Sigma

Six sigma is a common concept for people who have worked in statistics or operations research. It can be used by anyone in any business aspect.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

Statistics

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

External Links

How To

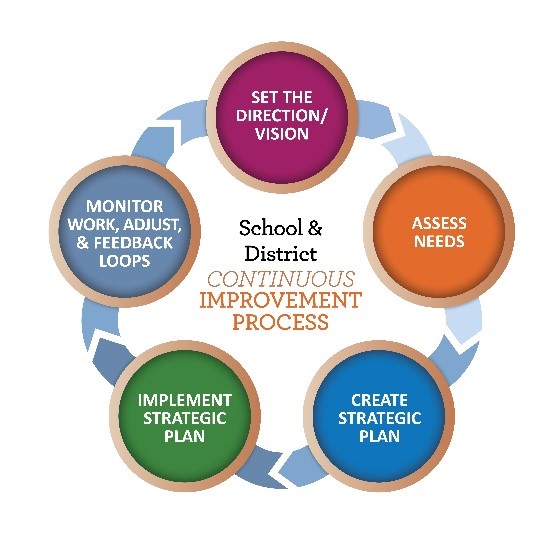

How do you apply the Kaizen method to your life?

Kaizen means continuous improvement. Kaizen is a Japanese concept that encourages constant improvement by small incremental changes. It is a process where people come together to improve their processes.

Kaizen is one of Lean Manufacturing's most efficient methods. In this concept, employees who are responsible for the production line must identify problems that exist during the manufacturing process and try to solve them before they become big issues. This improves the quality of products, while reducing the cost.

Kaizen is a way to raise awareness about what's happening around you. If something is wrong, it should be corrected immediately so that no problem occurs. If someone is aware of a problem at work, he/she should inform his/her manager immediately.

Kaizen has a set of basic principles that we all follow. We always start from the end product and move toward the beginning. If we want to improve our factory for example, we start by fixing the machines that make the final product. First, we fix machines that produce components. Next, we fix machines that produce raw material. We then fix the workers that work with those machines.

This approach is called 'kaizen' because it focuses on improving everything steps by step. We finish fixing the factory and then go back to the beginning. This continues until we achieve perfection.

How to measure kaizen's effectiveness in your business is essential to implement it. There are many methods to assess if kaizen works well. One way is to examine the amount of defects on the final products. Another way is to check how much productivity has grown since kaizen was implemented.

To determine if kaizen is effective, you should ask yourself why you chose to implement kaizen. Is it because the law required it or because you want to save money. Did you really believe that it would be a success factor?

If you answered yes to any one of these questions, congratulations! You are ready to start kaizen.